Walnut harvest usually begins in the southern and central valleys in early September and the northern regions in early October. If the weather permits, harvest normally wraps up before Thanksgiving

|

The walnuts are ready to be harvested when the green outer hull splits exposing the nut. At this time, many walnuts have already dropped from the trees to the orchard floor. Nuts that have not dropped naturally are then mechanically shaken from the tree. This is accomplished with a machine called a “shaker.” A shaker is a short sturdy vehicle with a claw attached to the end of a boom. The shaker operator gently grabs the tree trunk with the claw and vigorously shakes the tree until the remaining nuts fall to the ground. |

|

|

The next step is to bring in the sweepers. These small machines are designed to do one thing: sweep the nuts into wind rows using a combination of powerful air blowers and rotating rakes. Once the nuts are in wind rows, field workers rake away sticks as a mechanical nut harvester picks up the walnuts and transfers them into carts and then to large belly dump trailers. |

|

|

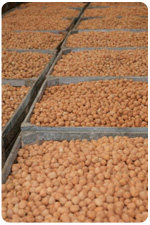

The walnuts are then taken to a hulling and drying facility where any remaining hulls are removed and the nuts are given a cleansing bath before passing over a sorting table. |

|

|

The walnuts are then delivered to the processing plant where additional cleaning and sorting takes place. At this point, the walnuts are either packed in sacks to be sold as “in-shell” product, or they are run through a shelling line where the nuts are cracked. |

|

|

The hulls are removed and the kernels are sorted using high-tech laser sorting machines and additional hand sorting. The kernels are then packed in corrugated cartons and passed through a metal detector. |

|

|

Finally, the walnut kernels are ready to be shipped to destinations around the world. |

|